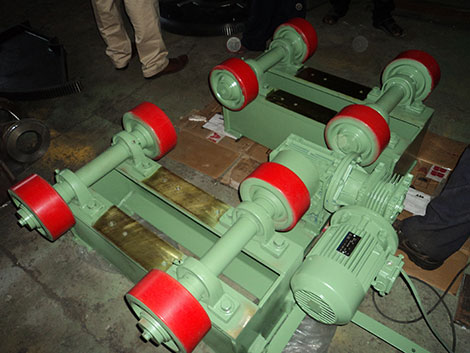

Pipe Welding Rotators

Cubuilt’s Pipe Welding Rotators have been specially designed to meet the modern requirements and incorporate features essential for efficient and economic welding. The basic function of this Pipe rotator is to turn the job continuously at a preset speed so that welding can be made on the circumference

In Drive Unit

Plummer blocks with Polyurethane Rollers are fixed on the mainframe. We have provided the fixed diameter setting i.e. According to the size of the job diameter. These types of rotators are very useful for pipe welding.

The Idler unit

The idler unit is the same as the Drive unit without drive arrangement and gears. While loading the job care must be taken that the job may not impact the bracket.

One Drive and One Idler can be used for up to 8 Meters long jobs. If a job is more than 8 meters in length, then extra idler Units are to be added.

Construction and Technical Details

The Pipe Welding Rotators are made extremely robust to withstand the harsh fabrication; shop handling by following simple instructions and timely maintenance, many years of trouble-free service can be obtained from these rotators.

Pipe Rollers Range

1 Ton to 2000 Ton Capacity

Features

- Increased Production

- Improved Quality of surface finish

- Less handling time

Looking for a reliable & stable partner?