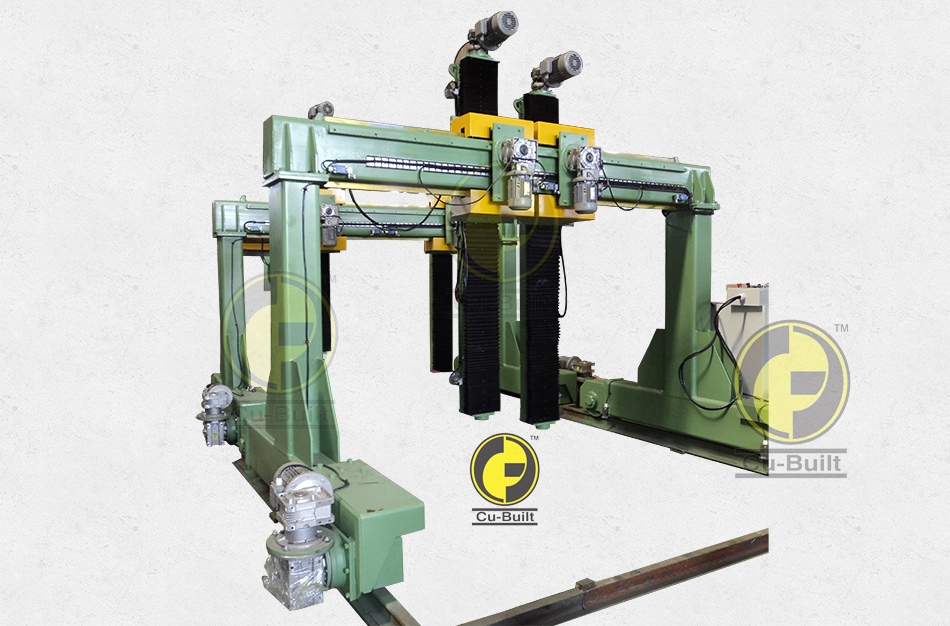

High-Precision Welding Gantry System for Structural Beam Fabrication

The Welding Gantry system is designed for longitudinal welding of structural beams with the web in a vertical position. This advanced system features active torch position compensation, ensuring precision and efficiency. The system integrates with MIG, MAG, or SAW welding equipment, making it adaptable to customer-specific requirements.

A key advantage of the welding gantry is its ability to maximize throughput by increasing weld deposition rates. Whether using SAW, MIG, or CMT welding, it significantly enhances efficiency in long horizontal welds. Built to meet precise workshop specifications, the system integrates seamlessly into production lines. With superior welding accuracy of up to 0.0039 inches (1/10 millimeter), it reduces defects, minimizes rework, and improves profitability.

The welding gantry system enhances workplace safety by reducing reliance on overhead cranes, minimizing operational hazards, and improving operator comfort. Its automated torch adjustment ensures consistent weld quality with real-time position compensation, making it a critical tool in structural steel fabrication, shipbuilding, railway manufacturing, oil and gas, and heavy equipment production.

With heavy-duty construction and user-friendly controls, the system allows operators to monitor and adjust welding parameters efficiently. The ability to integrate various welding processes enhances its versatility, making it a cost-effective solution for large-scale welding operations. By streamlining production, reducing manual labor, and ensuring high-quality welds, the welding gantry system significantly boosts productivity and maintains the highest standards.

Looking for a reliable & stable partner?